Scaling is known as one of the most critical issues and limitations in aqueous systems, which involves several industries. Applying an efficient, economical, and environmentally friendly solution to control scale formation is challenging. Scaling prevents efficient heat transfer by forming an insulated layer on the surface of heating elements. Moreover, scaling increases the pressure drop in the process and consequently, it raises maintenance costs and even leads to system shutdown. Using antiscalants is considered the most promising method to control scale formation. To this end, CHEMICAL TASFYEH CO-produced TGUARD scale inhibitors series are added to the process water. These compounds have received a lot of attention because they can control the deposition by the low values and coverage of several mechanisms that can be used simultaneously with the process and do not have significant waste. Antiscalants disrupt the scaling process through a variety of mechanisms including threshold effect, crystal modification, dispersion, or sequestration. Although antiscalants have several types in terms of their constituent materials, they all prevent the formation of Ca, Sr, Ba, and Mg deposits on the surface with high power. In the current study, various kinds of scales and anti-fouling, scale inhibition mechanism, advantages of antiscalants, and their applications, especially in oil and gas pipelines, are reviewed.

What are TGUARD antiscalant?

One of the biggest problems in industries with water consumption and water purification as well as seawater desalination is the presence of many salts that accumulate and deposit on the surface of equipment over time. Strontium sulfate (SrSO₄), barium sulfate (BaSO₄), calcium carbonate (CaCO₃), and calcium sulfate (CaSO₄) as well as silica deposits (SiO₂) are among the compounds that cause deposits. Excessive deposition and accumulation of these compounds lead to a phenomenon called scaling, which causes severe damage to the engine and other device equipment. For this reason, it is necessary to prevent sedimentation on these surfaces as much as possible in different ways.

The use of TGUARD anti-scalant materials, which are also known as anti-sediment, is one of the suitable solutions for this purpose, which has a significant effect on reducing the sediment. These materials have a phosphate and polymer base.

The different types of anti-scale or anti-fouling

Scale inhibitors can coarsely be classified as organic and inorganic. The inorganic types include condensed phosphate, such as poly(metaphosphate)s or phosphate salts. Suitable organic scale inhibitors available are poly(acrylic) acid (PAA), phosphino carboxylic acid, sulfonated polymers, and phosphonates. Phosphonates are maximally effective at elevated temperatures whereas sulfonated polymers are maximally effective at low temperatures. Copolymers that contain both phosphonate and sulfonate moieties can produce an enhanced scale inhibition over a range of temperatures.

In the phosphate type, these carboxylic and phosphate materials exist and have an extremely high power in reducing the sedimentation of water purification equipment. In another type, these materials, which have a polymer base, can prevent carbonate and sulfate deposits and are a practical option for use in the desalination process of sea water.

Scale inhibitors can be classified into three main groups:

- Thermodynamic inhibitors – complexing and chelating agents, suitable for specific scales.

- Kinetic inhibitors – for hydrate formation may also be effective in preventing scale deposition.

- Adherence inhibitors – surface active chemicals simply suppress the adherence of crystals to the metal surfaces.

In addition to being phosphate or polymer antifouling materials, they can also be divided into different groups based on the pH value, which are:

-

Acid antiscalant

One of the most important features of this group is their pH of less than three, which makes them very effective in removing calcium carbonate deposits and preventing the formation of calcium phosphate and iron deposits well.

-

Alkaline antiscalant

Anti-precipitation materials that have alkaline properties are among the practical options to prevent the deposition of various metals, such as aluminum and manganese, as well as iron. These materials have a phosphate base.

- Neutral antiscalant

Another group of antifouling materials, whose pH is between 5 and 6, acts neutrally and can be used with different membranes.

A very important point in the chemical formulation of anti-scalants or the formula of anti-sediment compounds is that these materials are completely different based on the pH level and the type of sediments in the water.

Types of Scales:

- Sulfide Scales

- Iron Sulfide

- Other Sulfide Scales

- Sulfate Scales

- Barium Sulfate

- Calcium Sulfate

- Carbonate Scales

Mechanism of Scale Inhibitions

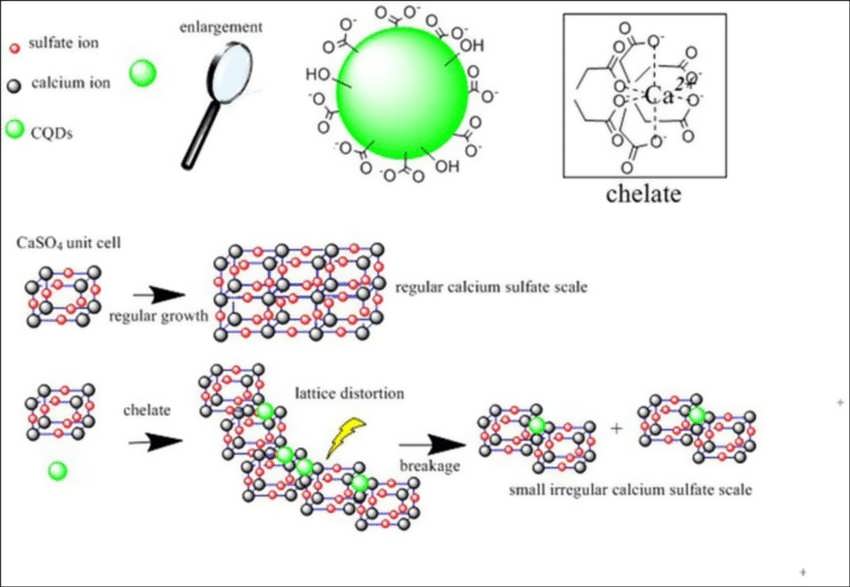

The mechanism of scale inhibition primarily depends on the chemical nature of inhibitors. It could be held in various ways, such as sequestering (or chelating) or threshold scale inhibitors. The mechanisms of scale inhibition by chemical inhibitors as a function of the surface conditioner to inhibit the scale formation are discussed below:

1.Chelants (Sequestrants)

Organic/inorganic molecules having chelating properties are used as inhibitors to prevent scaling. Ethylenediaminetetraacetic acid (EDTA), diethylenetriamine pentaacetic acid (DTPA), citric acid, and gluconic acid are typical examples of chelants. The function of chelating agents by chelation is to prevent scale formation. The anionic part of the inhibitor combines with the cationic part like the metal ion in the solution, resulting in the forming of a coordinate bond with the scaling cation. Depending on the combing stoichiometric ratio of cations and anions in the solution, the chelant molecules bond with scaling cations. The mechanism of scale inhibitions is shown.

Mechanism of scale inhibitions

2.Threshold Scale Inhibitors

This type of inhibitor has been used to prevent scale precipitation by delaying the crystal growth of the mineral/ore. They prevent the corrosion or deposition of scales by interfering in a single or more than one step of the formation of scales. In general, the creation of scales includes several steps, such as crystal growth, nucleation, agglomeration, and/or intervening in aggregation. Mechanisms are accumulated to function as primers or combinations of the distortion of the crystal, nucleation inhibition, threshold inhibition, and/or dispersion mechanisms. This type of mechanism is defined by adding a substoichiometric quantity of inhibitors that intermingles with growing crystals and delays crystal growth.

Applications of Scale inhibitor:

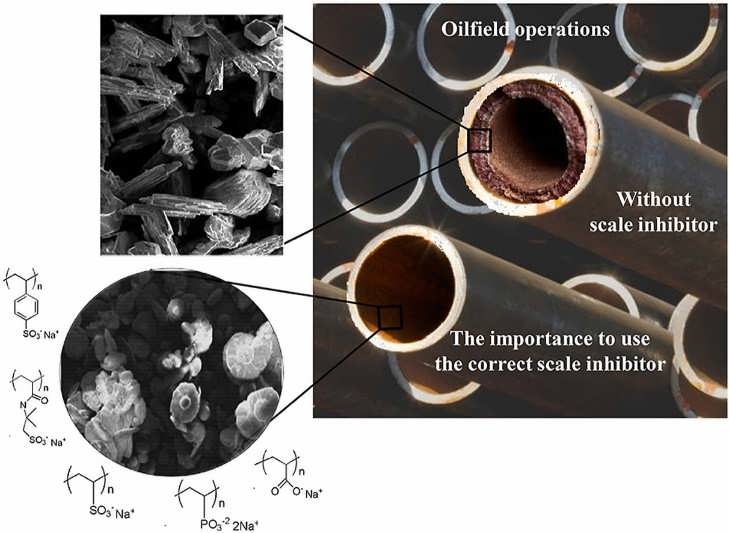

Scaling is a well-known precipitation caused by water in the petroleum industry. Scales are crystals that usually form in the pipelines and wellbores near the surface, downhole, and at surface equipment with fluctuations of thermodynamics, kinetics, and changes in pressure and temperature values. They are directly responsible for causing a reduction in production due to the decrease of the internal production tubing and pipeline diameters and in many cases can cause a total plug. Hence, the profitability of a development project can be impacted severely by scale presence.

The importance to use the correct inhibitor of in pipelines.

Role of scale inhibitor in pipelines.

Due to the great power of these materials in preventing deposits in equipment and devices, there are many applications for them. Among the applications of antiscalant, the following options can be mentioned:

- Removal of compounds prone to sediment formation in cooling and heating systems and boilers.

- Preventing the formation of deposits in the facilities of refineries and petrochemical industries

- Preventing the production of sediment in industrial desalination or RO devices

- Preventing sediment formation in nanofiltration and ultrafiltration

In addition to being phosphate or polymer antifouling materials, they can also be divided into different groups based on the pH value, which are:

-

Application of antiscalant in water purification

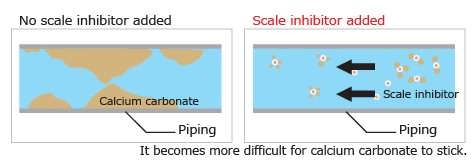

These materials strongly resist the formation of deposits on the membranes of industrial desalination and reverse osmosis devices. The formation of sediment on the membranes reduces their efficiency to a great extent and lowers the efficiency of the device in reducing water hardness. Anti-fouling materials are used for this purpose. The function of these materials is to prevent the formation of sediment on the membrane, causing a delay in the process of sediment formation.

-

Reverse Osmosis (RO) antiscalant

One of the main uses of these materials is reverse osmosis. Reverse osmosis antiscalant is injected into the system along with a small amount of acidic substances and prevents the formation of deposits on the membranes. Injected acidic substances prevent the formation of calcium carbonate and calcium phosphate deposits and adjust the value of the LSI index in the range of one to two.

As much as antiscalant can help increase the life of the reverse osmosis device, choosing the wrong type and using it incorrectly can damage this equipment. It is possible to point out the side effects of inappropriate antiscalants, creating an acidic environment in water and corrosion in equipment. In addition, not injecting it in the right amount causes a lot of sediment to form on the membranes. Sedimentation of the pores of the membranes over time puts a lot of pressure on the machine’s engine and also increases energy consumption to a great extent. In addition, over time, the water output from the device will decrease. The schematic of antiscalants in RO membrane scaling control is shown.

Schematic of antiscalants in RO membrane scaling control

Choosing the best antiscalant, and Calculating the amount of antiscalant injection

Antiscalant brands in Iran and foreign countries offer different features for their products. For this reason, there are differences in quality as well as density and pH, etc. in them. In choosing an antiscalant with the best quality and features, it is necessary to pay attention to the following:

-

Density

One of the most important things in choosing these materials is paying attention to their density. The appropriate type can be selected based on the desired fluid type.

-

pH

As mentioned, these antifouling materials have different acidic, alkaline, and neutral types and they differ in terms of performance. According to the desired fluid and the type of solutes, ions, and compounds in them, the ideal pH for an antiscalant should be chosen.

- Temperature

- Amount of TDS

- The flow rate

Benefits of antiscalant injection

The main reason for the high use of these materials is their many advantages and positive points, which include:

- Cost savings due to the high power in removing precipitating substances and low-dose injection

- Preventing the formation of sediment layers on the surface of membranes and industrial equipment

- Increasing the lifespan of the membranes and reducing the costs required to replace the filters

- Compatibility with the environment and non-production of dangerous and harmful compounds