A Comprehensive Guide to Hydrogen Sulfide Scavengers(h2s scavenger): Exploring Different Types, Mechanisms, and Their Impact on Industries

1. Introduction

Hydrogen sulfide scavengers play a crucial role in various industries, including oil and gas, wastewater treatment, and refining. These chemical compounds are used to remove hydrogen sulfide (H2S), a highly toxic and corrosive gas, from different processes and products.

H2S is a very dangerous and damaging gas that can be found in various sources of hydrocarbons, such as crude oil, natural gas, and refined petroleum products. It can harm both people and equipment. The use of hydrogen sulfide scavengers helps ensure safety, prevent equipment damage, and comply with environmental regulations.

In this comprehensive guide, we will explore different types of scavengers, such as triazine H2S scavenger, hemiacetal, acetal and glyoxal, their mechanisms of action, and their impact on industries. Whether you are a professional in the field or simply interested in understanding the chemistry behind hydrogen sulfide scavenging, this article will provide you with a deep understanding of this important topic.

Tasfyeh Group in Iran, as a forerunner in the production of various types of mercaptan scavenger and H2S scavenger chemical, including triazine and non-triazine, hydrogen sulphide scavenger without scaling helps you earn more knowledge about the different types of scavengers and choose the most suitable product for your industry.

In the following sections, we will delve into the different types of scavengers available in the market, their mechanisms of action, and their specific applications in various industries. Tasfyeh group helps you in understanding the role and effectiveness of different scavengers that will enable professionals to make informed decisions when it comes to the selection and implementation of H2S scavenging solutions. Stay tuned for more insights into this vital aspect of industrial operations.

2. Key Features of hydrogen sulphide scavenger

Hydrogen sulfide is a naturally occurring gas that may be generated during the production, processing, and transportation of hydrocarbons. It is often accompanied by sulfurous compounds and is known for its foul odor, resembling rotten eggs. In addition to its unpleasant smell, H2S is a highly toxic and corrosive gas that can pose serious health risks to humans and cause significant damage to infrastructure. The presence of H2S can lead to the deterioration of equipment, storage tanks and pipelines, resulting in costly repairs and downtime.

Furthermore, the emission of H2S into the environment can have adverse effects on air quality and contribute to pollution. It also can cause severe health issues, including respiratory problems, eye irritation, and even death at high concentrations.

Hydrogen sulfide can react with steel to form iron sulfide corrosion films, leading to pipeline degradation and potential leaks. Additionally, H2S can increase the acidity of the liquid or gas mixture, further exacerbating corrosion risks. Therefore, it is crucial to remove hydrogen sulfide from hydrocarbon streams promptly and efficiently.

3. Benefits of H2S scavengers

Hydrogen sulfide (H2S) scavengers are chemical compounds that are specifically designed to remove H2S from various industrial processes and products. These scavengers are of great importance in industries such as oil and gas, wastewater treatment, and refining, as they help ensure the safety of workers, protect equipment from corrosion, and comply with strict environmental regulations.

By effectively removing H2S, scavengers contribute to the overall productivity and efficiency of industrial processes while maintaining a safe working environment. These chemical compounds work by chemically reacting with H2S to neutralize its corrosive properties and prevent its release into the atmosphere.

These are special chemicals that react with and eliminate hydrogen sulfide selectively. They are designed to overcome the specific challenges posed by hydrogen sulfide and provide a more cost-effective alternative than conventional gas/liquid sweetening methods.

Totally H2S scavengers not only play a crucial role in mitigating health and safety risks but also have a significant impact on productivity in various industries.

In the oil and gas sector, the use of scavengers ensures the uninterrupted operation of drilling, production, refining, and transportation processes. By effectively removing H2S, equipment corrosion is minimized, equipment integrity is preserved, and maintenance costs are reduced. This ultimately leads to improved productivity and reduced downtime.

Wastewater treatment plants benefit from the implementation of scavengers as they prevent the formation of H2S gases, eliminating foul odors and improving the working environment for employees. Moreover, compliance with environmental regulations is ensured, avoiding potential fines and penalties.

4. Specifications

There are several different types of hydrogen sulfide (H2S) scavengers available in the market, each with its own unique characteristics and applications. The choice of scavenger depends on various factors such as the specific industry and process, concentration of H2S, temperature, pressure, and desired outcome.

- Liquid scavengers: these scavengers can be applied via continuous injection or used in H2S contactor towers, where production streams are passed through a vertical column of the product. They can be used downhole, including in deepwater fields; in multiphase, gas, or oil pipelines; or in refineries.

- Solid scavengers: These scavengers consist of solid materials that have a high affinity for H2 They are very effective in stripping H2S from gas streams down to trace levels. They generally do not require additional chemicals, and do not impact downstream processes or overboard water. They commonly use in applications where liquid scavengers may not be feasible, such as in gas pipelines or in situations where the H2S concentration is extremely high.

- Catalysts: these scavengers are designed specifically for treatment of H2S in natural gas in contact towers, and bubble towers.

On the other hand, we can say there are two categories of scavengers:

- Chemical scavengers that work by chemically reacting with H2S to form non-toxic compounds. Common examples include triazine-based scavengers, amine-based scavengers, and aldehyde-based scavengers and

- biological scavengers which utilize naturally occurring microorganisms to convert H2S into non-toxic substances. They are often used in wastewater treatment facilities and other industries where biological processes are already in place.

Regenerative and non-regenerative hydrogen sulfide scavengers are two types of scavengers used to remove H2S from gas streams. Both types of scavengers are used in various industries, including oil and gas, wastewater treatment, and hydrocarbon processing facilities.

| Type of H2S Scavenger | Advantages | Disadvantages |

| Generative H2S Scavengers |

|

|

| Non-Generative H2S Scavengers |

|

|

As the audiences of Tasfyeh group are oil and gas industry, we categorize the hydrogen sulfide scavengers according their solubility in water and oil.

Water-Soluble Scavengers

Water-soluble H2S and mercaptan scavengers (specially MEA Triazine H2S scavenger) are the most common type used in various applications, including crude oil, flare gas, LPG, residues, and condensate streams. These scavengers are preferred for applications with temperatures below 200F (93°C). They work by dissolving in water and reacting with hydrogen sulfide to form non-toxic byproducts that can be easily separated from the hydrocarbon stream.

Tasfyeh group manufactures various kinds of water-soluble H2S scavengers for use in downhole, production and transportation of oil that have potential customers from neighboring countries.

Oil-Soluble Scavengers

In high-temperature applications or situations where water tolerance of the hydrocarbon is a concern, oil-soluble H2S scavengers are utilized. The use of hydrogen sulfide scavengers is common in the oil and gas industry, including crude oil, natural gas, liquefied petroleum gas (LPG), steam-assisted gravity drainage (SAGD), and water flood systems.

These scavengers are typically based on amine compounds and are designed to dissolve in the hydrocarbon phase, allowing for efficient H2S removal. They are particularly effective in treating sour crude oils and other hydrocarbon liquids.

The injection dose rate of hydrogen sulfide scavenger for the treatment of crude oil depends on various factors such as pipe diameter, pipe length, gas molar mass velocity, inlet H2S concentration, and pressure. The most effective hydrogen sulfide scavenger and its injection dose rate for the treatment of crude oil may vary depending on the specific conditions and requirements of the industry.

Triazine-based sulfur scavengers can be both water-soluble and oil-soluble, depending on the specific application and the chemical structure of the Triazine.

Hydrogen sulfide scavenger Triazine is the most commonly used liquid H2S scavenger, and it can be tailored to better suit the application or disposal considerations by changing the substitutions in the chemical structure. Triazine-based scavengers have become the most widely used of the hydrogen sulfide scavenger chemicals in the oil and gas industry.

2,2′,2”-(hexahydro-1,3,5-triazine-1,3,5-triyl) tri ethanol offer several advantages over conventional scavengers, including higher reactivity, lower dosage requirements, and better compatibility with other chemical treatments. The glycol ether components, an oil-soluble hydrogen sulfide scavenger triazine, can be used in any type of sulfide-scavenging operation and significantly reduce corrosion problems found with conventional Triazine scavengers. Triazine-based scavengers can effectively remove H2S from a wide range of hydrocarbon streams, including crude oil, natural gas, and refined petroleum products.

Therefore, it is important to consult with hydrogen sulfide scavenger chemists in Tasfyeh group to determine the most effective type of Triazine-based sulfur scavenger and its solubility for a specific application in your industry.

Tsorb3400 is a product of MEA Triazine from Tasfyeh group that eliminates hydrogen sulfide gas from processing systems in a safe, efficient and fast way. It protects the assets and reduces the corrosion rate. It is suitable for water-based systems, where it reacts with H2S and produces a harmless byproduct. Tsorb3400 contains 1,3,5-Triazine-1,3,5(2H,4H,6H)-triethanol and other chemicals that enhance its performance. It prevents the damage of expensive drilling equipment caused by H2S gases.

It also avoids the loss of time and money due to high levels of corrosive gases. The byproducts of the reaction with H2S are soluble in water and can be removed easily with the water in the system.

In addition to Triazine-based scavengers, there is also non-nitrogen or non- triazine based H2S scavengers available in the market. These scavengers utilize many chemical reactions to remove H2S involving metal-based compounds or hemiacetal-based compounds. Metal-based scavengers are particularly suitable for high-temperature and high-H2S concentration applications, such as asphalt H2S scavenger. Hemiacetals are great when you expect no scale in your systems.

Herein Tasfyeh group introduces Tsorb3450. Tasfyeh Group, due to having specialized knowledge in this field and also producing various products as sulphide scavenger, after analyzing your industry can introduce you the most suitable scavenger according to your needs.

Mechanisms of hydrogen sulfide scavenging

There are various mechanisms through which hydrogen sulfide scavenger chemistry effectively remove H2S from industrial processes. Understanding these mechanisms is crucial in order to choose the most appropriate scavenger for specific applications.

Chemical scavengers primarily work through a redox reaction in which the scavenger molecule reacts with H2S to form non-toxic compounds. The precise reaction mechanism depends on the specific type of chemical scavenger used. However, the general mechanism involves the reaction of the scavenger with H2S to form a non-toxic compound, typically water or elemental sulfur. The reaction can occur via different pathways, including oxidation, reduction, and chemical absorption.

Non-oxidative scavengers do not change the valence state of the sulfur but chemically react with the H2S molecule to convert it into metal sulfides. On the other hand, oxidative scavengers by reacting with H2S, change the valence state of the sulfur atom from −2 to 0 (elemental sulfur) or higher.

Biological scavengers utilize naturally occurring microorganisms to metabolize H2S and convert it into non-toxic substances, such as sulfate. These microorganisms can be implemented in wastewater treatment plants and other industrial processes that already incorporate biological treatment methods.

Solid or catalyst scavengers function by adsorbing H2S onto their surface, allowing for the removal of H2S from gas and liquid streams. The solid scavenger materials have a high affinity for H2S, facilitating efficient removal even in high H2S concentration conditions.

Triazine reaction with H2S is considered as the reaction of sulphide with liquid H2S scavenger.

In the subsequent section, we will delve into the specific applications of these scavengers in different industries. Tasfyeh group by introducing the mechanisms of action helps industries to select the most suitable scavenger for their specific needs, ensuring effective removal of H2S and enhancing overall safety and productivity.

5. Application of hydrogen sulfide scavengers in various industries

H2S scavengers work by reacting with H2S to form a non-toxic compound, typically water or elemental sulfur. The scavengers can be tailor-made for applications in various industries, including hydrocarbon processing facilities, wastewater treatment, landfill gas, digester gas, and pulp & paper industries.

The effective removal of H2S is crucial in ensuring the safety and productivity of different industrial processes.

In the oil and gas industry, hydrogen sulfide scavengers play a significant role in mitigating the risks associated with H2S exposure. They are widely used in drilling, production, refining, and transportation operations. By utilizing the appropriate scavenger of Tasfyeh group productions, the industries can prevent H2S corrosion, protect equipment integrity, and enhance worker safety.

Some of the benefits of using Tsorb3400 are:

- It removes H2S quickly and permanently without affecting the quality of oil, gas or fuel

- It improves the safety of personnel

- It reduces the corrosion risk in equipment and pipelines

- It maintains the integrity of assets and reduces the costs of maintenance and replacement

- It enhances the production performance

- Its byproducts are water-soluble

In wastewater treatment plants, biological scavengers are commonly employed to efficiently remove H2S gases produced during the treatment process. These scavengers ensure compliance with environmental regulations and prevent foul odors.

In the mining industry, H2S is a byproduct of mineral extraction that poses serious health risks to workers. Hydrogen sulfide scavengers help maintain a safe working environment by eliminating H2S emissions and reducing the risk of accidents and health complications.

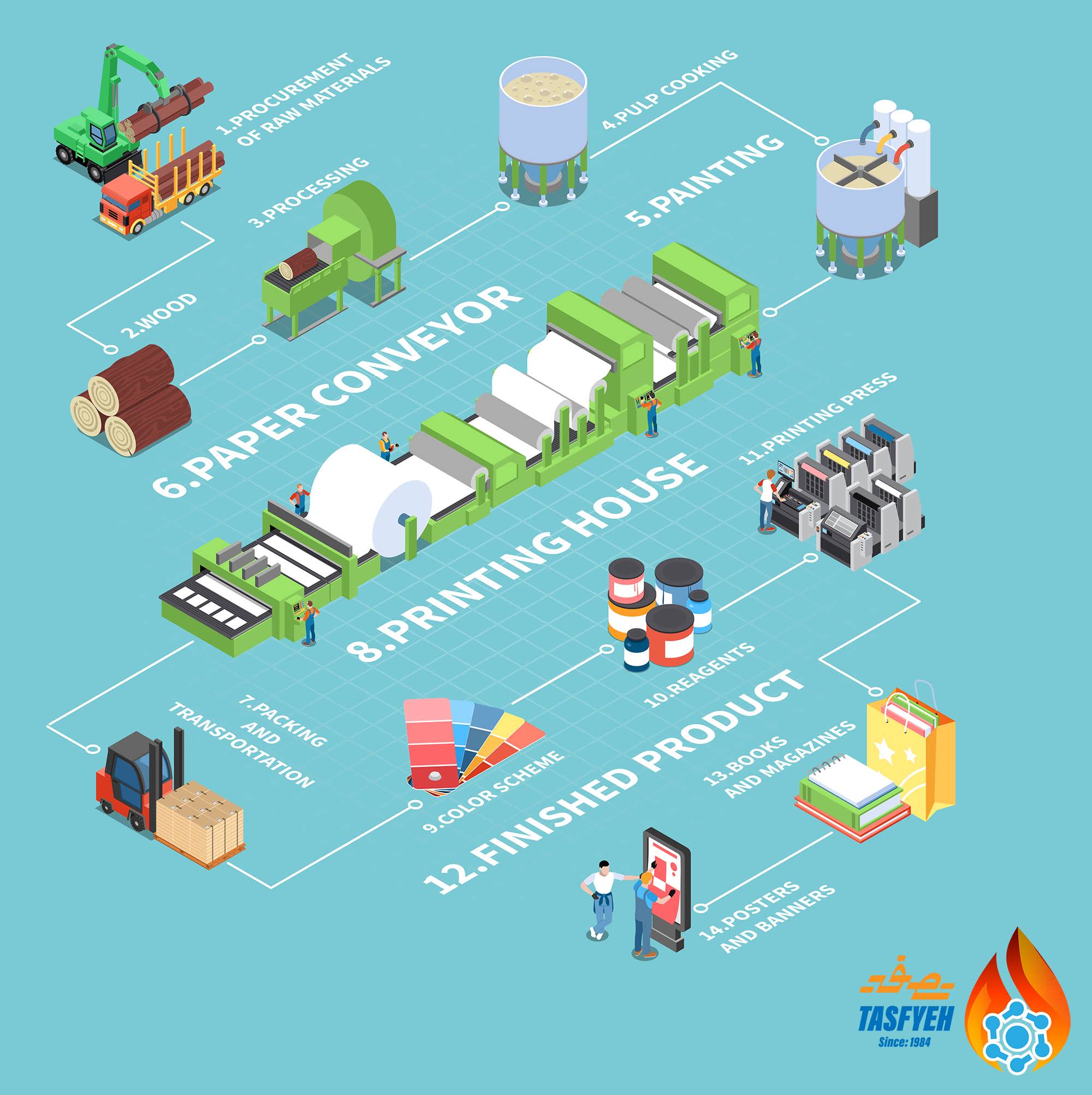

The pulp and paper industry also faces challenges associated with H2S emissions. By implementing suitable scavengers, this industry can effectively remove H2S from pulp digesters, reducing odor emissions and maintaining a safe workplace for employees.

Other industries, such as food processing, petrochemical, and wastewater treatment, can also benefit from the use of hydrogen sulfide scavengers to eliminate potential hazards and ensure compliance with safety regulations. You can use the advises of Tasfyeh group’s consultants to know more details about H2S scavenger chemicals in your own industry.

6. Why is it better to buy from Tasfyeh Group?

Tasfyeh group provides a wide range of water-soluble and oil-soluble scavengers regarding cost-effectiveness to mitigate the risks associated with H2S, including health hazards, infrastructure corrosion, and regulatory compliance. With the help of experienced consultants of the Tasfyeh group, you can choose the most suitable scavenger for your industry.

Our H2S scavengers specially MEA Triazine 80%, MEA Triazine 60%, MEA Triazine 50% and non-Triazine scavengers are tested and used in middle east Iraq, Iran, Azerbaijan, Kazakhstan and some other CIS countries.

One of the prominent areas of focus is the development of environmentally friendly and sustainable scavengers. Many industries are looking to reduce their environmental footprint and comply with stringent regulations, driving the need for greener alternatives. Researchers in Tasfyeh group are exploring novel materials and methods that can effectively remove hydrogen sulfide while minimizing their impact on the environment.

It is essential to consider factors such as temperature, water content, pH, and the presence of other contaminants when selecting the appropriate scavenger for a particular application. Tasfyeh group with relying on experienced technical experts in this field, can suggest the best H2S scavenger according to your environmental conditions. Also in case of possible problems, the technical team of this company will always be with you.

Furthermore, the cost-effectiveness of scavengers remains a critical consideration. Tasfyeh group finds cost-efficient solutions that meet the requirements of different industries.

So, order the products of the ،Tasfyeh group right now to ensure the maintenance of your equipment and the safety of your employees. If you have any question you can contact our experts.

7. conclusion

In this comprehensive guide to hydrogen sulfide scavengers, we have explored different types of scavengers, their mechanisms, and their impact on industries. We discussed the recent advancements in scavenging solutions and the challenges that industries face in their search for efficient and sustainable options.

Moreover, we recognized the significance of cost-effectiveness in the widespread adoption of scavengers. Industries are constantly striving to find economical solutions that meet their specific requirements.

By understanding the latest research and technologies in hydrogen sulfide scavenging, industries can adapt their management strategies to enhance safety and productivity.

Tasfyeh group is with you all this way. By trusting the purification group, you can get the best product according to your industry and benefit from our after-sales service.