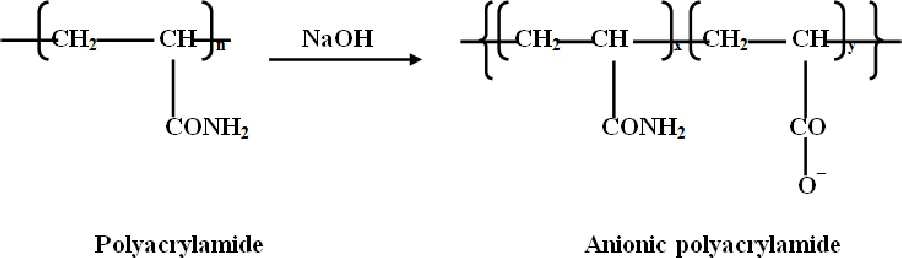

APAM or anionic polyacrylamide is repetition of acrylamide (-CONH2) which made structure [-CH2-CH(CONH2)-] n that n= repetition of monomers. anionic charge of polymer made whole charge number of polymer in water. according to polymer structure, length and charge each polymer shows specific properties which causes wide range of PAM can produce with several benefits and variant applications.

Anionic Polyacrylamide (APAM) is a polymer-based material used for erosion control, soil stabilization and reduction of amount positive ion in water (Ca2+ Fe3+ Mg2+) in various industries.

APAM applications shows the versatility and effectiveness of Anionic PAM in various industries such purifying drinking water and water clarification waste water, paper making, oil and gas hydraulic fracture. extraction of metals and hydrometallurgy, and obviously environmental protection.

Water treatments

In waste water treatments it plays a crucial role in flocculation processes, it can remove most suspended impurities and colloidal substances in water and wastewater. By neutralizing the charge of colloidal particles, polyacrylamide helps bring them together to form larger particles that can be easily precipitated and removed, leading to clearer water. In the other hand adsorbs on solid surfaces through interactions like electrostatic attraction and hydrogen bonding

Additionally, polyacrylamide can improve water quality, increase the strength and settling speed of flocs, reduce the amount of flocculant needed, and enhance the efficiency of sludge dewatering. It is also utilized in controlling soil erosion by improving the soil’s water retention capacity, reducing soil runoff, and sedimentation in waterways. Polyacrylamide is cost-effective, environmentally friendly, and versatile, making it an essential component in wastewater treatment processes

Dinking treatment

Anionic Polyacrylamide (APAM) polymer used in various industries, such as water treatment. In the context of drinking water treatment, APAM plays a important role in removing contaminants and improving water quality.

- Separate solids: APAM is uses in water treatment processes to separate solids and other contaminants from water. It is involved in many steps like coagulation, flocculation, sedimentation, and filtration. Polyacrylamide based flocculant reduces water hard ness and removes pollutants like suspended solids, organic matter, and heavy metals from drinking water, effectively.

- Metals and in organic removal: in this segments, anionic charge of APAM can help in the removal of inorganic materials like many heavy metals (cadmium, copper, lead, mercury), non-metallic salts (arsenic, selenium), and other contaminants.

- Polymeric containments: anionic flocculants can act as a polymeric adsorbent in drinking water treatment cost effectively, it can help to remove inorganic matter and balance pH levels.

Polyacrylamide aids in the coagulation of wastewater by neutralizing the charge of colloidal particles, facilitating their aggregation into larger flocs according to their molecular wight and charge can be easily removed. This process is crucial in water treatment as it helps in the efficient removal of suspended impurities and colloidal substances. Polyacrylamide enhances the coagulation process by reducing the amount of flocculant needed, improving water quality, increasing the strength and settling speed of flocs, and facilitating sludge dewatering. Additionally, polyacrylamide can help prevent corrosion and scaling in circulating cooling systems by reducing the deposition of inorganic materials. Overall, polyacrylamide is a versatile and effective tool in wastewater treatment processes, contributing to clearer water and improved water quality.

oil and gas

Polyacrylamide (PAM) in the oil and gas industry commonly uses for various applications, primarily in enhanced oil recovery processes EOR. In petroleum exploitation, polyacrylamide serves as a fracturing fluid additive, and oil-displacing agent in tertiary oil recovery methods. By improving rheology of injected fluid by increasing the viscosity of driving fluids and enhancing the efficiency of oil displacement can improve oil recovery.

Second in drilling fluid PAM can improve rheology of drilling fluids reduce fluid loss, and prevent sticking accidents carry cuttings, lubricate drill bits.

Third PAM plays as stabilizer in oil production by reducing water production, maintaining formation energy, and improving ultimate oil recovery and production.